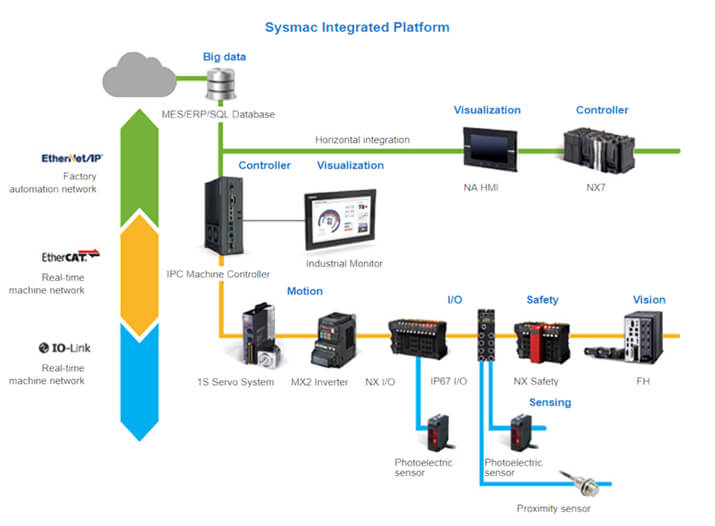

Adept engineers have pioneered in industry 4.0 development according to each customer requirements. Our in house mechanical and electrical design team allows us to respond to each client unique needs before actual development so that customers can simulate it, thereby streamlining the process. Industry 4.0 is a current trend of automation and data exchange in manufacturing industries. It includes cyber physical system, the internet of things, cloud computing and cognitive computing.

Industry 4.0 is commonly referred to as the 4th industrial revolution. In Industry 4.0 internet of things (IOT) connect and communicate people, sensor, machines and devices.

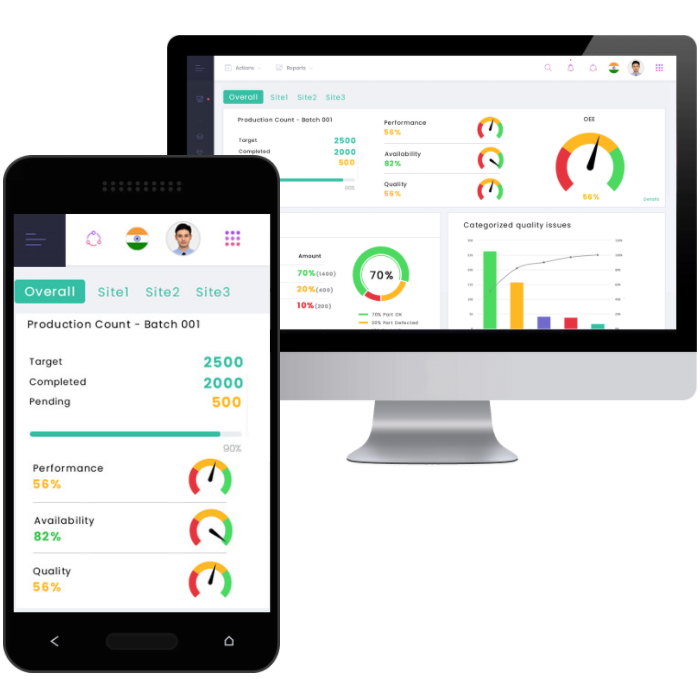

Industry 4.0 provide transparency to the organization by giving them needful information to make appropriate decisions.

In Industry 4.0 cyber physical system are used to make decision on their own and to perform their task as autonomously as possible.

Detect Anomalies and defects in Real-time through visual LED indicators

More efficient work:

In industry, Industry 4.0 make the work more efficient by reducing the product cost and maximum utilization of resources. Dreams of driverless cars are decades old. But with the help of 4.0 those fantasies are turning into reality. Adept Engineers have pioneered into the industry 4.0;our engineers always innovate customer friendly products.

Greater connectivity:

Business is always looking to support their decisions with data. Our I4.0 provide accurate data that is helpful to take decisions. By enhancing connectivity between every part of the supply chain, Industry 4.0 will hasten the transition from a linear structure to one that’s more responsive.

Light supply chain:

Both suppliers and original equipment manufacturers in the automotive industry are subject to increasingly stringent fuel regulations. Adept engineers design technology to light weighting to increase fuel economy. Industry 4.0 also helps the automotive industries to adapt new technologies in their industry.

Self-monitoring capabilities:

As industries are moving towards 24 hour productions equipment reliability becomes more critical. Adept Engineers design productsto identify potential maintenance issues before they cause downtime. That same process solutions can be used in various automotive sector to decrease unexpected breakdown.

Capacity of customization:

Today's car drivers consistently express the desire to customize their vehicle configuration.Industry 4.0 help automotive industry to customize customer vehicles and shorten the delivery time for those vehicles.

Network flexibility:

Industry 4.0 help to connect the customers who are present in different locations. If production and demand fluctuates, operation automatically gets shifted as per competitive market structure.